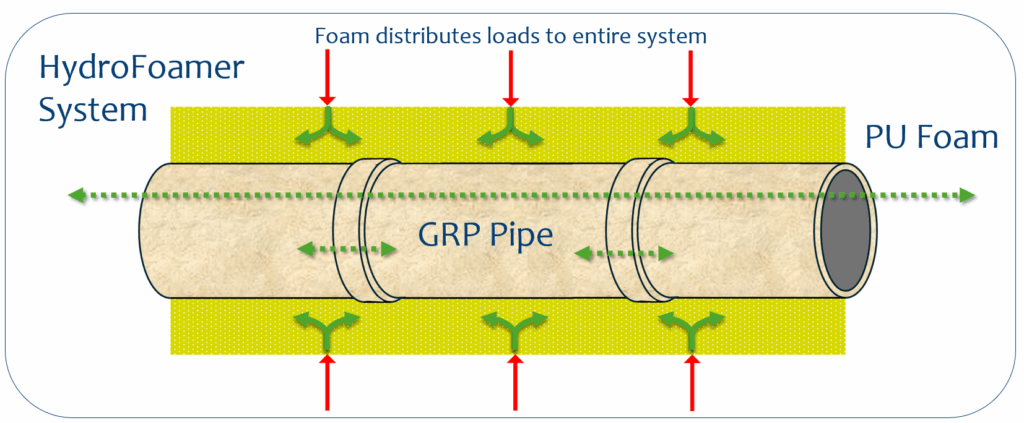

The HydroFoamer system was originally designed to apply rigid, closed-cell polyurethane (PU) foam to GRP pipelines in hydropower projects, but its core concept has proven adaptable across a much wider range of industrial and infrastructure applications. The system now supports a variety of sprayable materials—including polyisocyanurate (PIR), hybrid foams, and specialized polymer coatings—expanding its use into demanding environments such as oil & gas, mining, and chemical transport.

At its core, HydroFoamer enables the robotic application of a continuous, high-adhesion material layer across both straight and curved pipe sections. This forms a structural bond that effectively interlocks pipe segments, significantly reducing or even eliminating the need for traditional mechanical restraints such as thrust blocks, tie rods, flanges, or couplings. Our updated bend and joint deflection models—validated by analytical and field testing—demonstrate the system’s ability to manage both axial and transverse loads, even in unrestrained joint systems.

The HydroFoamer platform supports a wide range of pipe materials and geometries, with particular strength in composite and polymer-based systems such as GRP/FRP and HDPE. Pipe diameters from 300 mm to 2000 mm are currently supported, with operating pressures up to 40 BAR, and development is underway to extend this range further.

In oil & gas applications, the HydroFoamer system provides a corrosion-resistant, chemically inert, and thermally insulating envelope that is fully compatible with sour gas conditions and low to moderate cryogenic exposure. The use of PIR formulations further enhances flame resistance and long-term thermal performance, meeting critical safety and regulatory thresholds.

Each sector—whether water infrastructure, energy, or industrial transport—comes with distinct technical and compliance challenges. The HydroFoamer is engineered to meet these with a combination of flexible deployment, material adaptability, and rigorously tested mechanical performance.